Umatshini wokuwelda we-laser ophathwa ngesandla we-aluminiyam yentsimbi yentsimbi

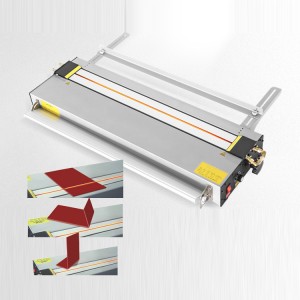

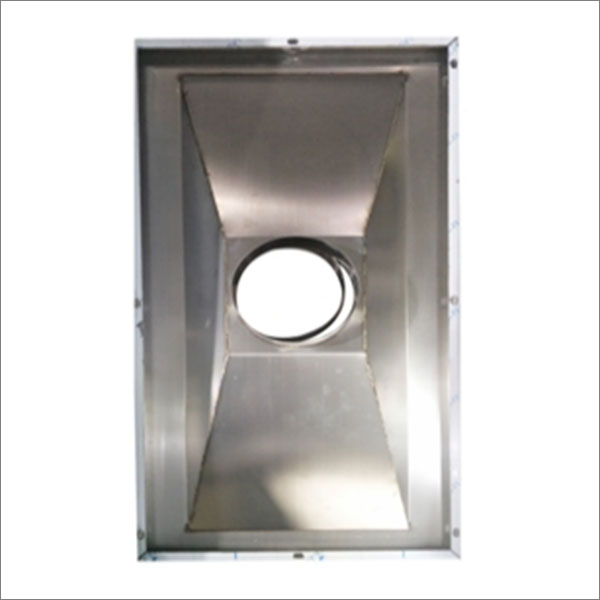

Umatshini wokuwelda we-laser ophathwa ngesandla, usebenzisa i-laser generator yamva nje.Ixhotyiswe ngentloko eshukumayo kunye nesithambiso socingo.Oomatshini babonakala kwimizi-mveliso yezixhobo ze-laser, bazalise indawo engenanto yokuwelda ngesandla.Ineenzuzo zokusebenza okulula, i-welding beam entle kunye nesantya esikhawulezayo se-welding.Welding in aluminiyam obhityileyo, sheet stainless-steel, sheet yentsimbi, sheet galvanized kunye nezinye izinto zentsimbi unokutshintsha ngokugqibeleleyo indawo argon arc welding, ukuwelda zombane kunye nezinye iinkqubo.Umatshini we-laser welding ophathwa ngesandla unokusetyenziswa ngokubanzi kwiikhabhathi, iikhikhini, izitebhisi, izinyusi, iiracks, ii-oveni, iingcango zentsimbi engenasici kunye neefestile zokugada, iibhokisi zokuhambisa, ikhaya lensimbi engenasici kunye namanye amashishini anzima kunye nenkqubo ye-welding engaqhelekanga.

| 1 | Imodeli yomatshini | Umatshini wokuwelda ifayibha laser ngesandla |

| 2 | amandla laser | 1000W, 1500W, 2000W, 3000W |

| 3 | laser wave ubude | 1070 NM |

| 4 | Ubude beFayibha | Standard10M Ubuninzi 15M |

| 5 | imo yokusebenza | Ukuqhubekeka/modareyitha |

| 6 | Uluhlu lwesantya sokuwelda | 0~120 mm/s |

| 7 | Ukupholisa i-chiller | I-industrial water chiller |

| 8 | Uluhlu lobushushu bendawo yokusebenza | 15 ~ 35 ℃ |

| 9 | Uluhlu lokufuma yendawo yokusebenza | < 70% Akukho ukujiya |

| 10 | Iingcebiso zokuwelding ubukhulu | 0.5-3mm |

| 11 | Iimfuno ze-welding gap | ≤0.5mm |

| 12 | amandla ombane osebenzayo | 220 V |

Ingasetyenziswa ngokubanzi kwiikhabhathi, ikhitshi, i-staircase elevator, ishelufa, i-oveni, umnyango wensimbi engenasici kunye nefestile yokugada, ibhokisi yokuhambisa, ikhaya lensimbi engenasici kunye namanye amashishini antsonkothileyo kunye neenkqubo zokuwelda ezingaqhelekanga.

Isantya welding 2-10 amaxesha ngokukhawuleza kunewelding yemveli.Umatshini omnye unokugcina ubuncinci be-welders ezi-2 ngonyaka.

Ukuwelda kweLaser

welding Traditional

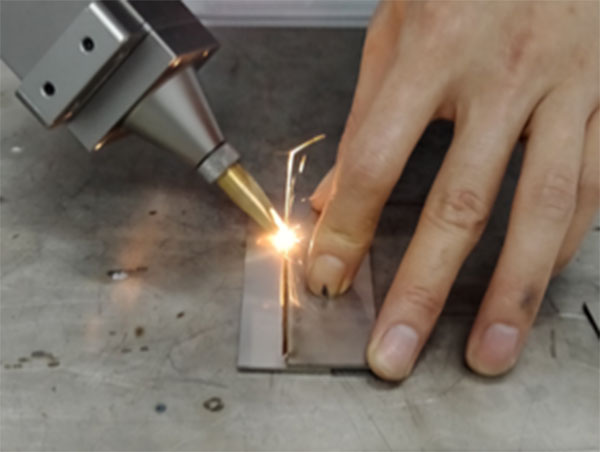

► Umsebenzi ulula, kwaye kunokwenzeka ukuba ungene emsebenzini ngaphandle kwesiqinisekiso somsebenzi, kwaye imveliso entle inokudityaniswa ngaphandle kotitshala.

I-Fillet welding, i-welding ethe nkqo

Ukuthunga ukuwelda

Ukwaleka ukuwelda

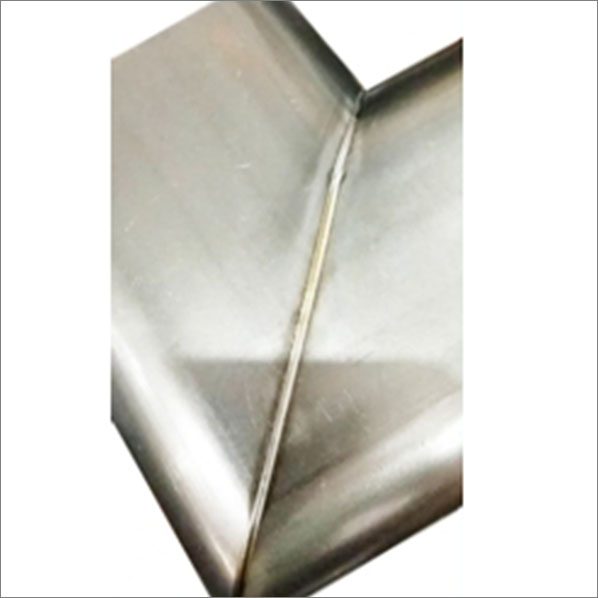

I-weld seam igudile kwaye intle, inciphisa inkqubo yokugaya elandelayo, ukonga ixesha kunye neendleko.

Akukho siva welding

Umhle weld

Akukho deformation ye workpiece

AbaziphuhlileyoWintloko ye-obble welding ihlawulela ukungonakali kwe-laser welding indawo encinci, yandisa uluhlu lonyamezelo lwamacandelo omatshini kunye nobubanzi be-weld, kwaye ifumana ukubunjwa kwe-weld engcono.

I-welding workpiece ayinayo i-deformation, ayikho i-weldingisiva, kwaye i-welding iqinile.

I-laser welding inezinto ezincinci kunye nobomi obude.

Ikhuselekile kwaye ihambelana nokusingqongileyo.